The Columbia River flows through one of the most scenic areas in the Pacific Northwest. The area includes wetlands and significant archeological sites. And it’s home to endangered species. That set of conditions posed a challenge for a large power utility needing to expand.

In that setting, Portland General Electric (PGE) faced a tough balancing act – how to meet rising demand while still providing affordable energy to a large, existing customer base. The Oregon power utility needed to add to its generating capacity, but not at the expense of quality service to more than 800,000 existing customers. The sensitive environment only added another degree of complexity to the mix.

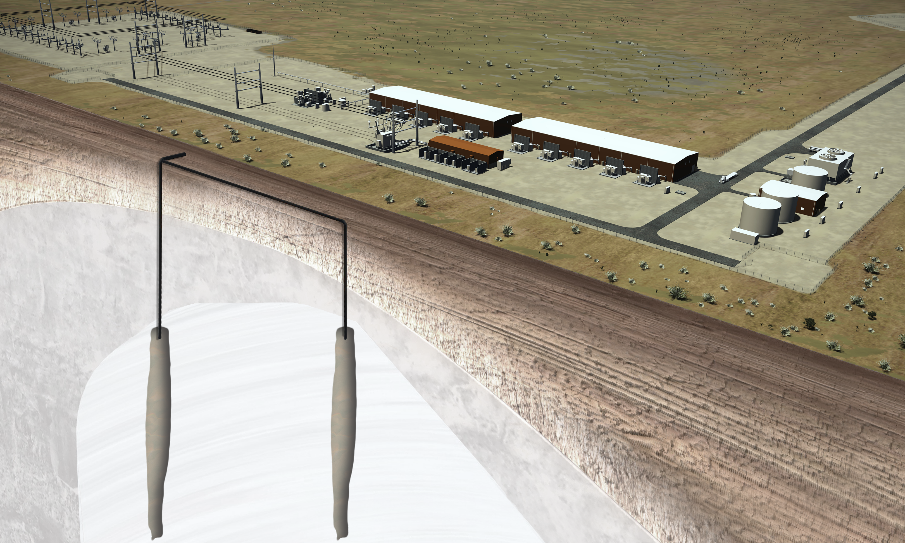

Black & Veatch solved the problem by designing an award-winning natural gas-fired plant, the 400 megawatt Port Westward Power Plant near Clatskanie, Oregon. Black & Veatch mitigated impact to the area by working with groups and individuals on many of the issues and concerns during the design and construction phases. Black & Veatch was also responsible for EPC and commissioning on the project. The plant was hailed as one of the top combustion turbine power plants in the world by Power Magazine.

Port Westward also meant major economic benefits for the community. Through its management of qualified local labor, Black & Veatch kept as much of the revenue from construction in the area as possible. In addition, preference was given to suppliers from PGE’s service area. During construction, the plant employed a peak of around 400 union construction workers, nearly all of them local.

The plant is highly efficient and uses the most advanced emission controls. Black & Veatch installed the super-efficient Mitsubishi G1 natural gas-fired combustion turbine. The G1 turbine boasts a combined-cycle efficiency that is among the best of any plant in the country. The plant’s net heat rate of 6,700 British thermal units per kilowatt hour takes into account all plant loads and transformer losses. The plant also employs the best available emission control technology, making it one of the cleanest of its kind.

PGE’s staff was involved from the outset in the design phase and was able to review Black & Veatch’s digital 3-D model throughout the design process. Black & Veatch provided detailed classroom training to address long-term operations and maintenance. In addition, PGE’s operation team was brought in 12 months before first fire to participate in plant training, commissioning and turnover activities to ensure a smooth transition from startup to operation.