In today’s dynamic liquefied natural gas (LNG) landscape, operators face increasing pressure to reduce capital and operating costs, simplify complex systems and accelerate project timelines — all while maintaining flexibility and reliability.

Black & Veatch’s PRICO® technology delivers on all fronts. With more than 60 years of global LNG experience and dozens of onshore and nearly half of the floating plants in operation globally, Black & Veatch is a trusted leader in delivering bankable, scalable and redeployable LNG solutions. Our proprietary PRICO process remains the cornerstone of our LNG and floating LNG (FLNG) offerings with continuous innovation.

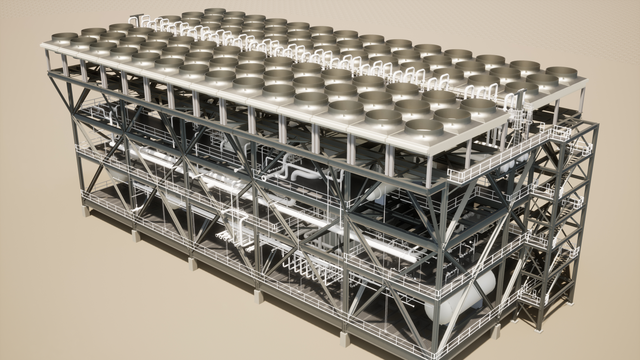

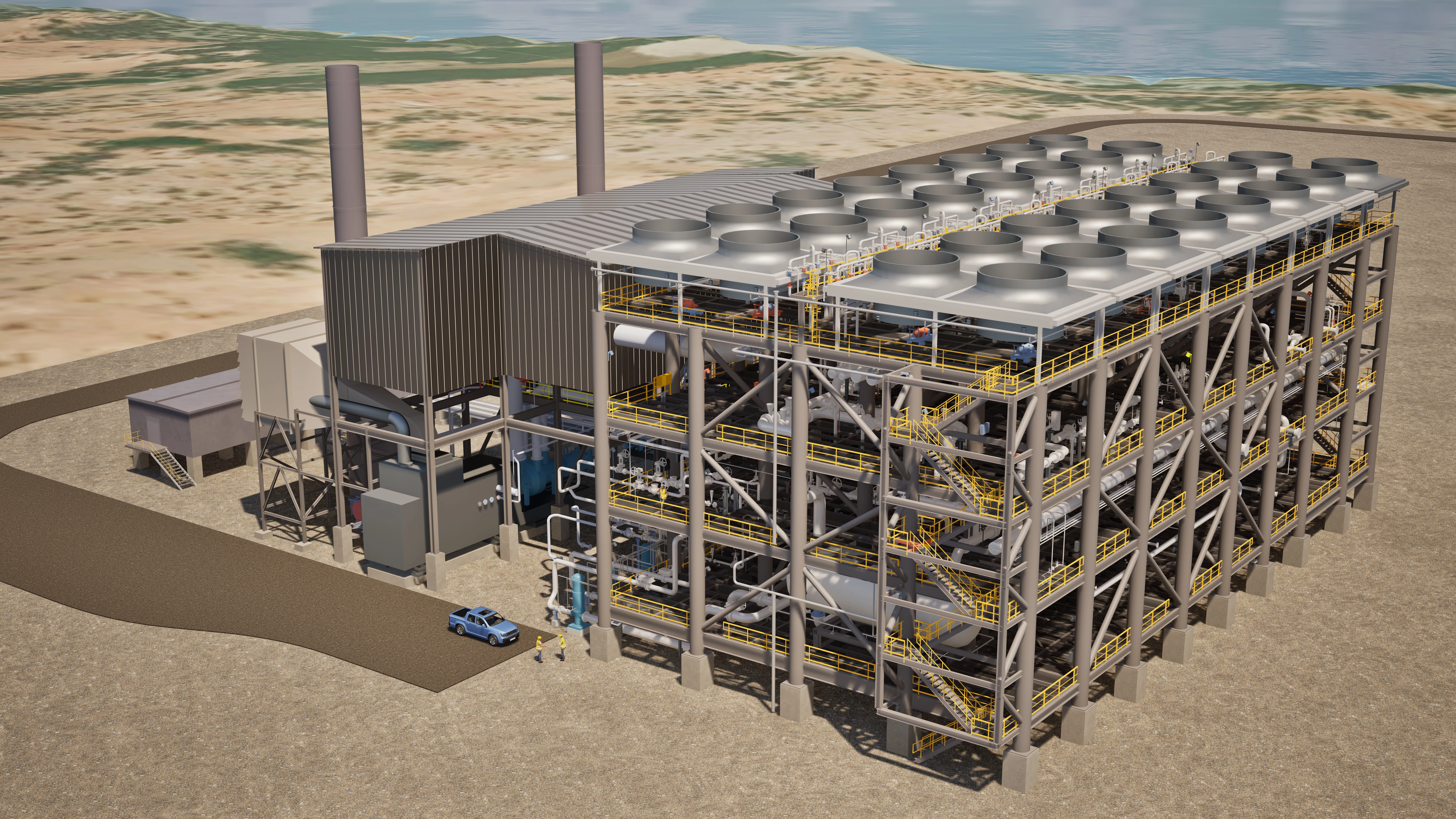

Modular LNG, maximum impact

Our modular PRICO technology offers unmatched flexibility and scalability, producing up to 2 million tonnes per annum (MTPA) per train in a compact footprint. This modular approach improves capital efficiency, accelerates schedules with lower execution risk and ensures operational certainty from pipeline to tank.

Whether driven by motors or turbines, PRICO modules are engineered to handle a wide range of gas compositions and site conditions, making them ideal for both onshore and offshore applications.

How PRICO® works: simplifying LNG liquefaction with SMR

The PRICO process uses a single mixed refrigerant (SMR) loop — a blend of nitrogen and hydrocarbons — to liquefy natural gas. This streamlined design reduces the number of components, simplifies operations and enhances reliability. The result: lower costs, faster startups and easier maintenance.

Contact Us

Looking for a partner in innovation?

Let's Talk