New understanding about the effects of solids treatment processes on per- and polyfluoroalkyl substances (PFAS) signals a leap forward in the effort to manage the contaminant.

Research funded by The Water Research Foundation and led by Black & Veatch studied the effects of drying on PFAS in biosolids. Drying, which removes water from solids, is a conventional processing step at water resource recovery facilities (WRRFs), aka wastewater treatment plants. The research offers hope that drying may be a feasible treatment method for managing PFAS in the biosolids produced by WRRFs.

Joining Black & Veatch engineers and scientists, researchers from Marquette University, California State University in Bakersfield and Eurofins Environment Testing contributed to the study. Published in the peer-reviewed Royal Society of Chemistry, the new understanding also highlights the need for further study because of the complexities involved in PFAS management. The research revealed what happened, but more work is to be done to understand why.

The need to consider PFAS in biosolids management

Treating sewage, WRRFs produce sludge. The sludge is then treated further to create biosolids, nutrient-rich organic material that is used as fertilizer and for soil conditioning in agriculture, landscaping, and land reclamation. Nowhere in the process do WRRFs actually produce PFAS. Nonetheless, the human-made chemical compounds are transforming how facilities manage biosolids.

There are thousands of PFAS, all designed for chemical stability. Their resistance to effects from heat, water and oil is why PFAS are abundant in consumer products: food wrappers, weather-proof clothing, stain-resistant fabrics, cosmetics, non-stick cookware, fire-fighting foam. The list goes on. Their stability also makes them resistant to environmental forces and treatment processes. PFAS simply endure. As a result of their widespread use and durability, the compounds make their way to WRRFs. Effective biosolids management therefore depends on knowing how handling technologies affect PFAS in the system.

Confirming that drying reduces PFAS in biosolids

PFAS management understanding and technologies for water and wastewater systems are rapidly evolving. Thermal processes such as gasification and pyrolysis have gained attention thanks to their potential to reduce PFAS concentrations in biosolids. They’re emerging technologies, yet conventional drying precedes their application in the biosolids production process.

This combination of new (technologies) and tried-and-true (drying) caught the attention of The Water Research Foundation and Black & Veatch. Drying removes water – including the PFAS in it. With drying well-established and widely used in solids handling, many utilities have a potentially valuable PFAS solution already in operation at their WRRFs. Yet, the effects of drying to the PFAS profile in biosolids have been largely overlooked by the research community. Separate from the effects of thermal conversion, the objective for the research team was to understand: What is the impact of drying? How does it affect the fate of PFAS in biosolids?

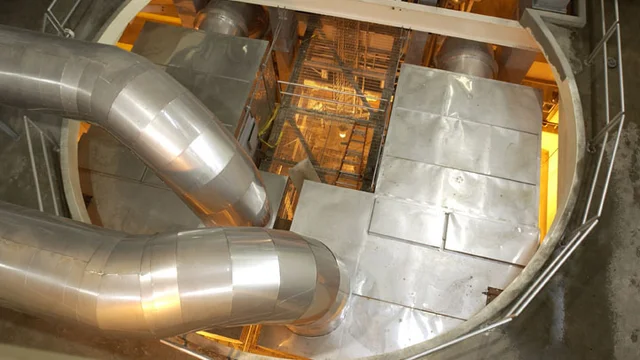

For answers, the Black & Veatch-led team explored samples from a full-scale dryer and conducted lab-scale experiments on biosolids from various utilities.

Though studies into drying’s impacts on PFAS have been limited, the research confirmed certain understandings. It showed that drying alters the PFAS profile of biosolids, not removing it to below reporting limits, but substantially reducing its total concentration.

The research also highlighted the need for further investigation. Understanding the fate of PFAS during treatment, whether from advanced thermal or traditional drying processes, means understanding whether PFAS are removed, transformed, or destroyed, and moreover where do PFAS that are removed go? For utilities, these distinctions are critical in terms of their efforts to manage PFAS. For example, a potential area for further study is how drying, while reducing PFAS concentrations in biosolids, might result in airborne PFAS or waterborne PFAS in condensate.

Discovery: learning more about PFAS mitigation

Source reduction is the most important and effective way to mitigate PFAS contamination of wastewater solids. Meanwhile, it is essential to understand the impact that all treatment processes have on changing the PFAS profile in biosolids. As the research led by Black & Veatch shows, drying could be one such process – not emerging but already widely used – that utilities have in their arsenal. Drying offers potential – it shrinks PFAS levels in biosolids. The next step is to understand why. With more research into drying’s impacts, understanding the true fate of PFAS may be determined – and even greater control of it attained.

Access the research published in the Environmental Science: Water Research & Technology, and learn more about teaming with Black & Veatch for effective PFAS solutions, from applied research to project execution.